IQF TUNNEL Freezers

our iqf TUNNEL freezers

AGF Freezers offers reliable, cost effective IQF tunnel freezers with a wide range of capacities customizable to various plant layouts and client needs. From French Fries to fruits and vegetables, the tunnel freezer delivers optimized separation, fluidization, and airflow control to carefully handle products and eliminate clumping.

The tunnel’s stainless steel construction enhances hygiene and meets food safety standards. High-efficiency fans and evaporators ensure superior IQF freezing performance and reduced operating costs.

Fully welded, insulated stainless steel floor construction with insulated panels

Non-slip sloped sanitary floor design with integrated drains

Robust stainless steel conveyor construction

Raised internal supports to give easy access for maintenance and cleanability

Recirculated Clean-in-Place (CIP) system for efficient sanitation

Sequential defrost system to ensure extended uptime

Pre-assembled components for quick on-site installation

construction highlights

Fluidization Technology

Gentle product fluidization through a combination of mechanical force and airflow

Chain driven eccentric UHMW blocks for mechanically separating products

Centrifugal fan impellers to generate uniform pressure zone to fluidize product

Customized fluidization process to eliminate product clumping and sticking

Two conveyor, cascade arrangement for crust and finish freezing

Plastic and metal belting options are offered to match your production needs. The belting design allows for optimal airflow and precise control over the freezing/chilling process, while ensuring efficient and reliable product transportation that maintains the integrity of the food.

Belting

PLC and HMI systems optimize the tunnel freezer’s performance, reliability, and user experience. PLCs provide automation and precise control of temperature and defrost cycles, while HMIs offer intuitive interfaces for monitoring, adjustments, and real-time information.

Control Panel

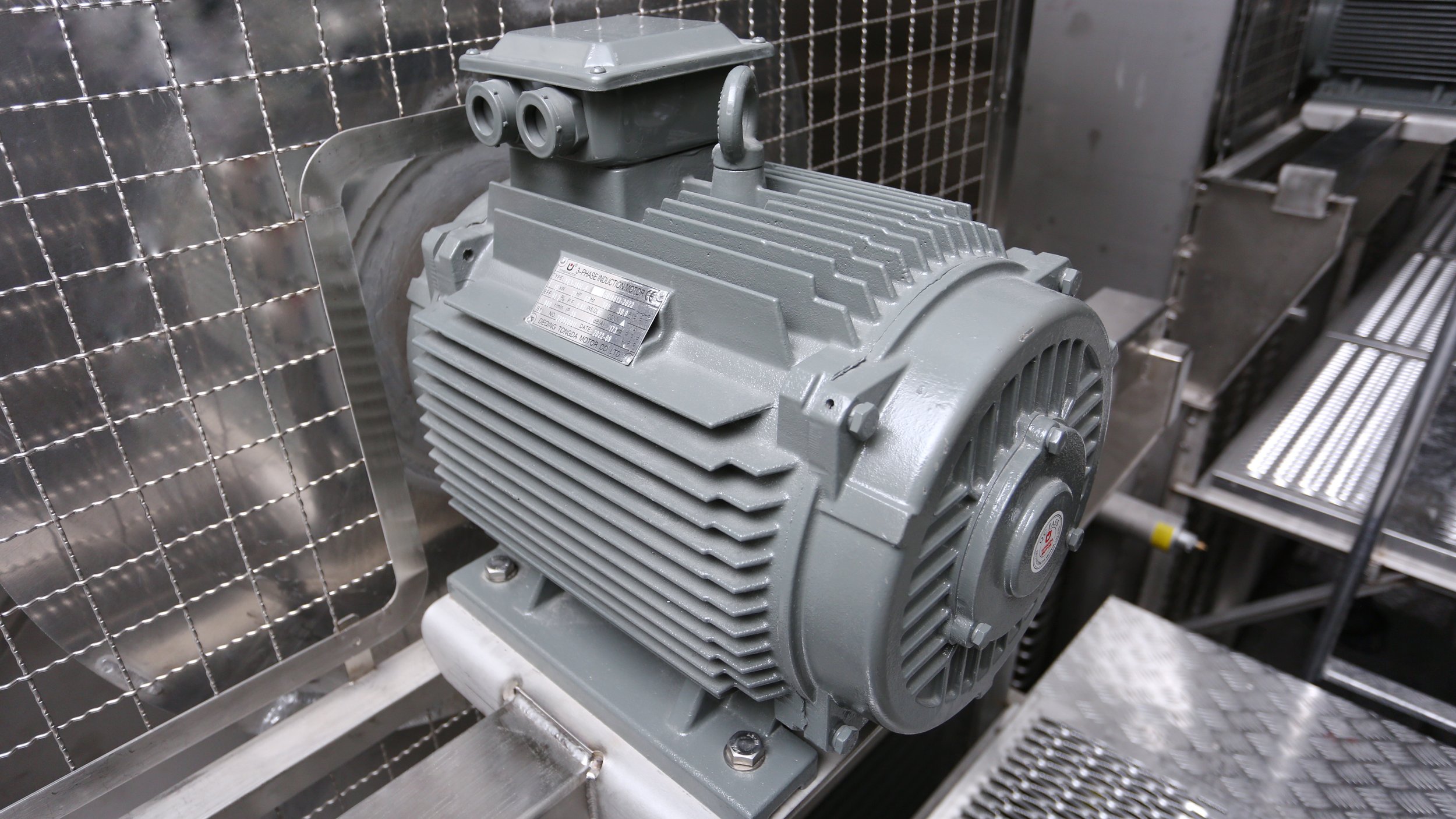

Electrical drive technology provides precise control of motor speed, belt movement, and fan operation. By utilizing electric motors, power electronics, and control systems, it enables energy-efficient freezing of individual food products, ensuring uniformity and high quality.

Motor & Drive

AGF IQF TUNNEL Freezers

Case Study

AGF IQF TUNNEL DRIVES SIGNIFICANT PRODUCTION INCREASES AND ENSURES CONSISTENT QUALITY FOR RIO FUTURO

“Since implementing the AGF tunnel, we’ve seen a significant increase in our daily capacity. The tunnel is incredibly energy efficient, consuming much less power compared to other options we considered. AGF's after sales service has been excellent. We plan to install additional tunnels as part of our master plan and look forward to working with AGF.”

Claudio Tapia Sáez, Plant Manager, Rio Futuro